Spring Latches

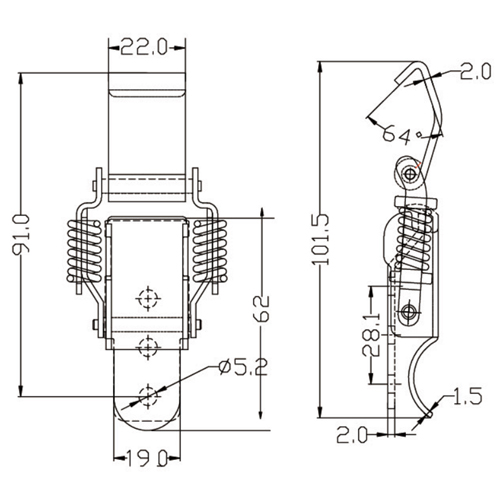

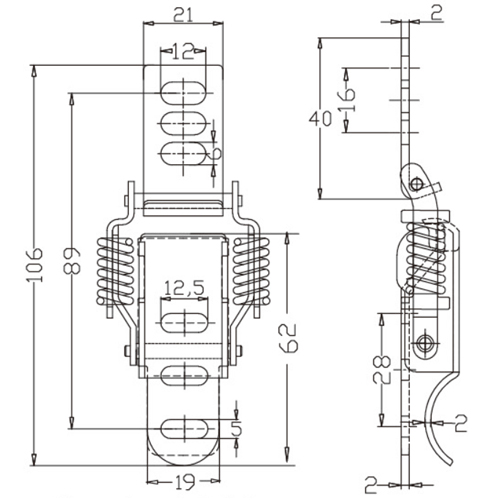

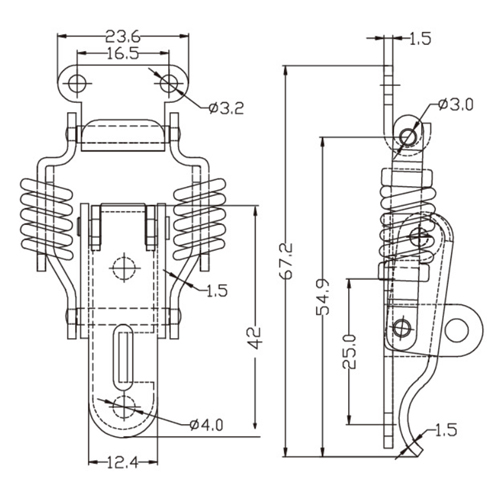

These spring latches locked with a spring compression so it’s not released due to vibration. The arm made from stainless steel so it’s rustproof and tightening strength is enough.

A powerful spring claw toggle latch is built-in so it’s suitable for vibration equipment. The spring-loaded latch mechanism ensures that you get to do the job easily and efficiently.

The spring toggle latches are widely used in automotive,industry applications, ventilation, air conditioning,industrial enclosures,industrial machinery, specially-equipped vehicles,containers and machine tools, automotive, trucks, cases,construction equipment, off-highway vehicles, farm equipment,industrial enclosures,industrial machinery, machine tools, metal cutting,garden equipment. Heavy-duty spring latch can be an ideal choice for more intense applications.

The spring latches have two various material:steel or 201 stainless steel,304 stainless steel. These spring loaded latches finish can be nickel-plated, chrome-plated, zinc plated. Tumbled for stainless steel.

Rochehardware is a professional spring latches manufacturer in China, our clients are proud of our spring latches’ quality.we are continually seeking new chest latches to fill needs that have not yet been met. We persist driven to satisfy, driven to deliver a spring latches product line that exceeds your expectations in price, quality, and delivery.

Import these spring latches to skyrocket your business.

CEO Notes

Hey! This is Robin, Roche Industrial Co.,Ltd Product CEO. Thanks to visit our website,and I hope to be a friend with you here. I have over 10 years experience in flight case hardware,I would like to share my experience in this field,and any questions you have about case hardware ,I'm happy to help you. I provide free consultant for many clients,and if you need any help on flight case hardware,reach me any time with below button.

Resources To Know More About Flight Case Hardware

Comprehensive Guide about Spring Toggle Latch

Work holding and the need for spring latch is an often ignored part of the machine work.

Normally, workers and operators put materials into industrial equipment for hold and stability.

Nevertheless, the proper hold is vital for safety and precision.

When materials slip during a machine process, there are more consequences than having an off-specification product.

Yes! It can cause great harm!

Finally, when work holding fails, it’s not typical for machines to become damaged and injuries to happen to operators.

That’s why it’s crucial to assess and understand the different kinds of work holding industrial equipment and hardware as well as their applications.

And one of this industrial hardware is spring latches.

CHAPTER 1: What Is a Spring Latch?

A spring latch is locked with a spring compression, so it is not released because of vibration.

Its arm is made from stainless steel thus it’s rustproof and tightening strength is sufficient.

A strong spring is made for the vibration equipment.

These spring toggle latches are widely utilized in different applications like:

- Automotive

- Industry

- Ventilation

- Air conditioning

- Industrial enclosures

- Specially-equipped vehicles

- Industrial machinery

- Machine tools and containers

- Trucks

- Automotive

- Off-highway vehicles

- Construction equipment

- Cases

- Garden equipment

- Metal cutting

- Machine tools

- And more!

Spring latches have two different materials:

- 304 stainless steel

- 201 stainless steel

Spring latches finish could be nickel plated, zinc plated, chrome plated and tumbled for stainless steel.

Draw latches work on the principle of drawing two objects together with tension.

The major components of a draw latch assembly are:

- The blade

It’s a hooked plate or a wide made loop

- The Keeper

It’s a hooked plate which gets the blade

- The hinge

It’s the one that allows the open and close movement

The tension is made when the blade is hooked to the keeper and clamped down.

For standard draw latches, the tension is free if the latch is rotated to a vertical position.

It’s applied once the latch is rotated to a horizontal position.

These toggle latches are complemented by a wide array of matching strike plates.

They are manufactured from either stainless steel or cold rolled steel.

What’s more:

They also feature countless options including vibration proof models, like the adjustable latches.

That’s to offer padlockable, key lockable, and gasket pull up types.

A few have a secondary locking feature to avoid accidental unlocking.

CHAPTER 2: Understanding Spring Latch System

When we talk about products, the easiest and fastest solution that has the highest possible quality is normally desired.

This fast-fix outlook goes for almost any industry, small or big.

One small and simple item which can provide fast solutions is a latch.

A spring-loaded latch is a latch which utilizes the spring to actuate the latch.

That aids to return the bolt to a default position if not in use.

Let us explain:

It’s typically in the closed position.

If the latch isn’t in use, the bolt is pushed forward engaging the keep until someone opens it.

The bolt is pushed back from the spring eliminating the bolt from the keeper.

Photo Courtesy: Alema Hardware

A spring latch system is quite simple.

In the simplistic structure, the size can differ somewhat a bit while the overall design is more likely to be across applications.

A metal frame holds the bolt.

Around the bolt, there’s a spring that’s always fixed to push the bolt to the further out position.

A variety of manufacturers makes spring latch system locks.

They have comparatively different designs, but they serve the same function and provide similar security measures.

A single-latch lock is spring loaded.

They feature a rounded metal ends which project from an open door.

The spring latch retracts as it glides past the door frame and discharges.

It mounts securely within the hollow plate on the attached door frame.

Where do spring latch systems make your day-to-day life easier?

Have you desired something you were utilizing this kind of latch system?

Are you now interested how does a spring latch work?

Continue reading to know more.

CHAPTER 3: How Does a Spring Latch Work?

It’s already mentioned that there is an abundance of latch types which are regularly utilized in all aspects of life.

However, a spring latch is the type of latch that stands out.

This particular type has some attributes which other latches don’t make it desirable in some cases.

Can you guess what it is?

The Structure of a Spring Latch

Once the bolt is pulled, the spring compresses. It disengages the bolt from whatever it is holding together.

Once released, the bolt fires forward to its resting position along with a decompressed spring.

A simple way to picture how a spring latch works is like launching a pinball.

When a quarter is put into the machine, there’s a ball that pops out and rests on the bolt.

However, if you pull back the bolt, you’ll notice a tension from the spring surrounding the bolt.

If you release the bolt on the pinball machine, there’s a forward force exerted into the ball.

That makes it launch into play.

Compared to pinball machines, spring latches are utilized to hold two (2) components altogether, either closed or open.

The job of the latches is to ensure neither component is moved from that preferred position.

The spring latch works the same to a deadbolt, but there’s a difference.

As an alternative to the push-pull action needed for a deadbolt to engage and disengage, one movement is essential.

That’s because the spring performs the rest of the work for fast detachment.

Spring latches can be utilized in a wide array of applications.

It can be from industrial, HVAC, railway, vehicles and machines, and a lot more.

The fast release mechanism of a spring latch makes latching quick and simple for any applications which it’s utilized on.

CHAPTER 4: Common Materials Used for Spring Latches

Durability is a crucial consideration in your spring latch.

The materials they are typically made from are the highest quality metals which do well outdoors and can endure the elements.

You will find a price difference between every substance.

In this chapter, we will give you the pros and cons of every spring latch materials like brass, bronze, aluminum, iron, and spring latch stainless.

Brassfor that Aged Look

Brass is one of the materials that is least conventional utilized in outdoor latches.

But if you want the look of the colonial design, it’s a perfect option.

It’s a heavy metal which feels hefty in your hand.

It also adds an excellent design element to your door.

The only possible drawback to this spring latch force material is that it will tarnish over time.

While you might enjoy its aged appearance, it’s crucial to maintain the surface.

After all, you want to keep the surface to preserve the life of the device.

Stainless Steel for a Modern Look

Spring latch stainless steel is somewhat a distant cousin to aluminum.

Stainless steel has the similar appearance to aluminum, but it’s a much heavier metal.

It’s strong and less likely to bend, warp and dent under temperature or pressure.

While it’s a bit costly, it’s a good material for a durable latch spring force.

It’s normally utilized in contemporary and modern designs.

It’s rust-resistant, and you will notice it in its raw silver form.

Powdered coated models are accessible.

It offers them an added layer of protection if you reside in a corrosive environment such as near the beach.

There are two types of stainless steel spring latch material:

- 304 Stainless Steel

304 stainless steel is the most typical form of stainless steel utilized around the globe.

That’s because of its superb corrosion resistance and value.

It’s composed of 16% and 24% chromium and about 35% nickel.

It also has small amounts of manganese and carbon.

The most typical form of 304 stainless steel is 18/8 or 18-8 stainless steel.

It comprises 185 nickel and 17% chromium.

304 can endure corrosion from the majority of oxidizing acids.

That durability makes it easy to sanitize.

That makes it perfect to use for food and kitchen applications.

It’s also typical in buildings, site furnishings, décor, and even hardware like spring latches.

The only disadvantage of this material is that it’s susceptible to corrosion from chloride solutions.

Chloride ions can make localized zones of corrosion, known as “pitting.”

It can range beneath protective chromium barriers to settle internal structures.

- 201 Stainless Steel

On the other hand, 201 is a genuine chromium-nickel-manganese stainless steel.

It was made to conserve nickel.

201 is the lowest cost option to traditional Cr-Ni stainless steel like 304 and 301.

The additions of nitrogen and manganese substitute nickel.

It’s non-hardenable by thermal treatment.

201 stainless steel is non-magnetic in the annealed condition.

But it becomes magnetic if cold worked.

Bronze that Ages Well

One of the costliest materials on the list is the bronze.

It’s a significant material which ages well.

It’s a famous option for those establishments with high-end design taste.

It offers a beautiful look, and it feels dense to touch.

The majority of spring latch designs are made with an element of imagination.

They feature old-world, contemporary and traditional elements.

The metals ages well and it does not need a powder coat to finish it.

It eradicates the risk of chipping or the necessity to refinish it over time.

Aluminum for Durability and Functionality

If you are worried about corrosion or wear and tear, aluminum might be the perfect material for you.

It is both durable and lightweight.

It has a natural resistance to corrosive elements.

It can also be utilized in any environment.

It’s a much brittle material compared to iron spring latches.

While you can buy designs in the conventional shiny silver color of the metal, aluminum spring latches are often powder coated.

They are coordinated with other spring latch hardware in more rustic colors such as black.

Typically, aluminum spring latches are the least expensive of the list.

It won’t limit your style options.

It’s made into the modern, traditional, antique and old world designs.

The metal is both functional and attractive as well.

Iron for All Door and Gate Style

Iron is the most commonly used spring latch material.

It’s crafted in a wide array of ways including traditional, colonial, antique, and old-world styles.

Manufacturers like Roche use both wrought iron and cast iron as it has a huge and stately look.

That looks great against your fencing.

The metal commonly gets a powder-black coating to offer it a layer of protection against the elements outdoors.

However, it might not be a perfect option if you reside in a place with many corrosive elements.

Seaside or beachfront homeowners might wish to look for another material.

That’s because the salt in the water and air could cause the spring latch’s mechanisms to rust rashly.

In normal cases, iron lasts a long period, and it provides a great value for its price.

CHAPTER 5: All the Details about Toggle Latches: Choosing the Right Spring Latch for You

Now that you understand the different materials and how each work, there are further questions to ask which may affect your shopping decision.

If you are searching for products which provide an added layer of reliability which serves a special purpose, there are spring latches that might be a better fit for you.

How to Choose the Right Spring Latch for You?

Toggle latches offer an elegant solution to equipment accessibility.

When they are locked, it provides secure fastening.

What’s more:

With the use of a unique cam action, a spring toggle latch is

- Stable

- Dependable

- Strong

Yet the fast release function denotes that it can be opened in a flash.

In case you didn’t know yet:

The wide array of such products denotes that there’s one to fit most applications.

It varies from high strength units capable of enduring approximately 7,000 kg force.

It can be through discreet draw latches utilized on machinery and equipment.

Isn’t that astonishing?

The core principle behind a toggle latch is that of calibrated cam action.

It guarantees once the latch is closed, it is locked in position too.

A specific force should be exerted to overcome the cam though.

The operation is simple, thanks to the leverage given by the handle.

It’s the length of which that identifies the needed force.

A few different terms are utilized to describe a spring toggle latch. It includes:

- Draw Latch

- Quick release fasteners

- Over center fasteners

- Pull-Action Latch

- Lever Latch

- Tension Latch

All of which have a similar definition.

What are the Types of Toggle Latch?

Apart from spring toggle latch, there is a different range of latches.

This range guarantees that there is a model to fit most applications. These are:

- Flush Fitting Latch – Utilized in panels where a smooth finish is needed.

- Under center Latch – It’s a light-duty latch along with a reversed handle.

Often, it’s called as draw latch.

- FlexibleFastener – Integrates extensible nylon and rubber components, which do the same function as the spring.

- Adjustable Fastener – The position of the claw could be adjusted. It can be done through a rod to get the needed tension.

- Spring Latch – The claw is made from curved spring steel. It expands as the latch is closed. An option is a mechanism or claws integrating coil springs.

- Rigid Claw – It’s a non-adjustable latch along with a rigid claw. It’s recommended to use a rubber seal to offer some resilience.

Maximum Load Values of Spring Latches

Items are accessible in a wide array of configuration to meet the needs of the customers.

Whether you are particular about sleek design, durability, customization or flexibility, you’ll find the right latching solution for you.

What’s more:

Spring toggle latches are categorized into different groups.

That’s to help our customers to get the right product.

When choosing a spring toggle latch, you need to determine the maximum load first.

You see:

Every latch is made for a maximum load.

No wonder:

It’s recommended to utilize a safe working load which is half its tensile strength.

The strength of the catch plate must equal to that of the spring latch.

Normally, there are four categories of spring toggle latches:

- Light Duty – Its ultimate tensile strength differs between 11 kilograms and 90 kilograms.

- Medium Duty – It’s made for the application needed, an ultimate tensile strength between 125 kilograms and 750 kilograms.

- Heavy Duty – It utilizes spring latches with a UTS between 1,000 kilogram and 2,500 kilogram.

- Super Heavy Duty – With an ultimate tensile strength of 7,000 kilograms.

If needed, further locking features can be identified.

Luckily:

Such might be to avoid tampering, theft, or because the installation is subject to extreme vibration.

That could lead the spring latch to open.

Thus, added locking features consists of:

- Keylock – A discreet keylock integrated inside the spring latch.

- Padlock – For additional security, a padlock does the similar function as a sealing pin.

- Sealing Pin – It’s a spring-loaded pin which avoids the catch opening.

- Safety Catch – The fastener can’t be opened unless the safety catch is free.

After understanding the ins and outs of spring toggle latches, what’s next?

Different Series of Latches

This time, we’ll discuss the different series of spring latches that are available today:

- 700 Series Latches

This series provides the widest selection with over 200 different products.

Different finishes, materials, countless sizes, different base plates, and screw loop designs.

Such draw latches are the convenient option for panel latching if catch plate requires to be connected in the distance from the latch.

- 800 Series Latches

The 800 series is the strongest and most robust spring latches.

They are the biggest as well.

Latches were made to meet the requirements of customers for harshest environments where dependable duty fasteners are required.

Such special purpose includes:

- Mining industries

- Railway

- Vehicles and machines

- 900 Series Latches

These latches have a subtle design along with hidden mechanism.

In spite of the minimalist look, products offer secure and strong latching.

They’re accessible in 3 different sizes and are preferred option for those who want the sleek design.

Locking Angle of Draw Latch

In a standard scenario where the point attachment is in line with the base of the spring latch, all the standard draw latches can be utilized.

Remember that the locking angle is at least 15 degrees.

On the other hand:

In a scenario where the point of attachment is past the mounting surface, several pressures might be lost.

But, how can that happen?

It may be because of the excessive over the center movement.

Further:

When a straight wire link is utilized, the connection might be slack.

Now, perhaps you’re asking yourself:

“How can I lessen such possibilities?”

To answer your question:

The attachment hole could be pierced on the center line of the pivoting hole.

The result?

It will lead to a decrease in the over the center movement.

But, wait – we don’t stop there.

Do you experience a scenario where the point of attachment is beyond the mounting surface?

Well, the two angle spring latches could be utilized in this case.

Such spring latches could be formed at their base to the appropriate angle.

You can reach the point of attachment.

Thus, keeping the proper locking angle.

Fair enough, right?

CHAPTER 6: Benefits of Using Spring Latches

Toggle latches are one of the many essential devices a person must own.

They firmly hold a workpiece, keeping it fixed.

Following are some of the top advantages of using spring latches.

- Efficiency

Installation of spring toggle latch is fast and easy. The clamps have extreme operating reliability as well.

The highly effective setup of spring latch allows you to work accurately and faster.

Photo Courtesy: SRM Trading

Because of its high locking ability, the materials needed for an application are reduced significantly.

That lessens work time substantially.

- Adaptability

Spring toggle latches can adapt to workpieces of different heights.

Most of the assortment includes from over-center latches.

These offer secure panels latching in different applications.

The preferred option when catch plate requires to be connected in the distance – at an angle or flat from the latch itself.

Through rotating the threaded screw loop, it’s possible to adjust the needed distance to catch the plate.

You will also find adjustable latches that come in an attractive design for securing parts which must often be opened.

- Versatility

Several kinds of spring latches are accessible on the market today.

Of all commercial latches on the market, spring toggle latch has the most varieties.

Aspects like:

- handle design

- handle placement

- pressure ratings

distinguish one spring latch from another.

The latches are also accessible both in automatic and manual models.

That enables for a comprehensive range of latch action. The spring latches are also accessible in different finishes.

It also improves corrosion resistance.

An example of this is:

- nickel plated

- chrome finish

- stainless steel

- zinc plated

- Enhanced Safety

The design of spring toggle latches guarantees you of an extreme level when working.

The positive locking action maintains both the tool and the workpiece securely in place.

That helps to avoid incidents due to slipping or loose grip.

Are you still with me?

The majority of spring latches enable you to exert a high level of force into the workpiece.

The superior holding power is a huge increase in overall safety while working.

Fasteners are utilized in the majority of devices to activate power latches. Such often needed frequent actions.

It also boosts muscle strains and fatigue. It also subjects the equipment to enhanced wear and tears.

Good news!

Spring toggle latches are made to allow a safer way of running the equipment.

That’s because of the lever mechanism that needs a single pull.

Then, it will activate all the power latches through the same circuit of power.

- Ergonomics

Spring toggle latches are made to lessen strain while working.

That enables you to make the most of on work efficiency.

The latches can be modified easily.

That aids you prevent strain injuries, fatigue and related concerns as you work.

Spring toggle latches are supplied in 304 stainless steel or mild steel materials.

It’s perfect for latch based applications including:

- Machinery

- Industrial enclosures

- HVAC

- Cabinets

- Enclosures and more

Other Benefits and Applications of Spring Latches

- Latches are supplied in various models

- Perfect for industrial cleaning machines, packaging and more

- Spring latches can be operated by hand and given with fast and easy feature

- Suits perfectly for securing locking and pulling off two components together

CHAPTER 7: Buy the Best Spring Latch for Any Application

Are you now searching for the best spring latch manufacturer?

Well, Roche got you covered!

We are your hardware specialists, so we can surely help you with your spring latch necessities!

Our draw latches work perfectly in applications.

These are applications which need to have some changes in alignment.

However, a tight seal is still required.

Roche provides parts along with a key-locking version.

Some of our items provide a padlock loop which can be utilized to safeguard your items.

What’s more:

When durability is your concern, pick a heavy duty spring load latch.

Do you have a more informal application?

Then we suggest that you pick our plastic latches.

Here at Rochehardware, you will find countless of spring latch items to choose from.

And our spring latch catalog is always growing.

That’s mainly because we work with customers just like you regularly.

We strive to make the design custom hardware industry better!

From plastic spring latches to oversized metal latches, we’ve got you covered!

Our design and engineering department has what it takes to offer you with a spring latch which suits your specific application.

More Reasons to Choose Roche as Your #1 Spring Toggle Latch Manufacturer

Are you having a difficult time with your toggle latches?

Are you happy with your existing spring latch hardware supplier?

Do you prefer a dependable spring latch hardware manufacturer that will offer efficiency to your work or business?

No problem!

Rochehardware is here to serve you!

Roche has more than 12 years of experience in providing high-quality spring latches.

We are the leading manufacturer of various toggle latch hardware around the world.

You can depend on our quality because our company has passed Rohs and ISO certification.

Do you think we’re exaggerating?

Rochehardware has a superb and experienced design team.

We also have a manufacturing factory with more than 2,000 molds in stocks that will save you cash.

We also have:

- top class die casting technology

- remarkable polishing technology

- top-notch surface treatment technology

- expert QC inspection as well as;

- reliable packing team

Roche has more than 12 years of experience in exporting spring latches to Australia, North America, and European markets.

We are also equipped with necessary information about the spring toggle latches hardware market than those local dealers out there!

No doubt about it:

Roche understands spring latch hardware and accessories.

We also understand all your requirements, as well as the entire spring latch type hardware and accessories available in the market.

What does this mean to you?

Roche will guide you gain more income with our high-quality spring latches!

What’s more:

We export 20 million sets of top-quality spring latches to the international market each year.

Plus! We offer super fast delivery as well!

We strive to guarantee the best quality at all times.

So each set of Roche spring toggle latches are 100% inspected before shipping.

Rochehardware strives to be the leading spring toggle latch manufacturer for our clients!

Allow Roche today to support you!

Do you think you can handle this thing?

Conclusion

Spring latch hardware is considered to be a crucial component in your home.

After all the discussions about spring latches, perhaps you are considering a place to shop.

Rochehardware is the answer to your problem!

We offer a wide array of spring latch for sale that will surely suit your budget.

You can’t typically purchase spring latches individually at your standard home improvement store.

But you can find it with us!

If you prefer to change your spring latch too, make sure to bring the old one with you.

Or you make certain you are aware of the style and model number of your old latch.

Hopefully, we’ve provided you with everything you need to know about spring latches.

Now, it’s you time to choose.

Are you ready?

Do you think you can pick the best spring toggle latches for your needs?

Do you need some assistance?

Don’t worry, we are only one click away!

If you want to know more of our high-quality spring latches, you can view it at our website today.

We have the best selections of spring latches!